Euroguarco Skid & Pressure Vessel Division was born for the scope to provide a global solution for medium-size EPC projects, offering basic and detailed Engineering, Procurement and Construction Services for the following industries:

Euroguarco offer for skid solutions includes:

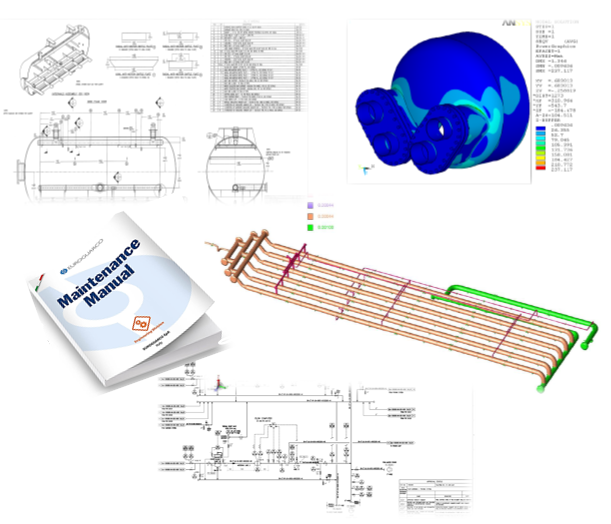

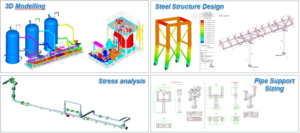

| Basic Engineering • Conceptual design development • Feasibility studies • Basic design development • H&MB, PFD and P&ID preparation • Design and control philosophy • Functional specifications for process systems • Process data sheets • Procurement • Fabrication • Modular Process Package & Assembly • Inspection & Testing • Packing and Delivery Detailed Engineering up to as-built • Piping & layout • Civil & structural • Electrical • Instrumentation & automation • Technical specification • Bid technical evaluation • Follow up of suppliers activities and vendor drawings • Operating, safety and maintenance manuals • Commissioning, start up and shut down procedures |

|

Some examples of Process Packages & Systems Skids are:

Examples of Pressure Vessel are:

The design of above packages shall be in full accordance with client’s specifications and the international standards ASME, PED, API, TEMA, etc. Materials of construction in carbon steel, stainless steel and special alloys as per client’s request.

Production units Manufacturing and plant design activity are carried out in the following workshops: Head Office: Via Terralba, 9 – Arcola (SP) – Italy Operation, Engineering, Procurement, Expediting Localita’ Vignola, 10 – Moscazzano (CR) – Italy Engineering and Prefabrication and Production

Main facilities and equipment for pressure vessel and skid unit activities: Euroguarco Group currently employs over 140 people including managers, engineers, technicians, administrative employees and workers. The personnel of this business unit has an average working experience of 20 years in the engineering & construction projects. All testing requirements of applicable construction codes or additional client’s requirements are satisfied whether in-house with SNT-TC-1A/ISO 9712 qualified personnel or by external labs. The production facility area is composed by 2 main buildings for a total covered space of approx. 5000 sqm, with main equipment:

Certifications: Most of the certifications required for pressure vessel, valves, piping and equipment manufacturing processes are available in Euroguarco or its partners of Italplant, which Euroguarco is the leading company of: ISO 9001 for the design and construction of boilers, vessels, heat exchangers, desalters, cycles for the production of energy, industrial plants, metal structures and tank containers as well as fittings, flanges, gaskets, bolts & nuts; API 6D for ball valves; BS OHSAS 18001 for safety and health in the workplace; “CE” PED business sectors; ASME U-Stamp, S-Stamp and R-Stamp; registration with the National Board and accredited by I.R.C.A.