Expanded flexible graphite is a highly conformable material, free of organic components, used for sealing service at high temperatures, in the presence of mechanical and thermal cycles, steam, hydrocarbons, and most chemicals.

Product lines:

Product range:

Flexible graphite gasket sheets, laminated with a variety of reinforcing inserts (stainless steel, aluminium, fiberglass fabric, etc.), are used for fabrication of flat gaskets showing excellent creep strength and good sealability also at low gasket stress and with irregular flanges.

Standard sheet size: 1000 x 1000 and 1500 x 1500 mm.

Standard sheet thickness: 0.3 ÷ 3 mm

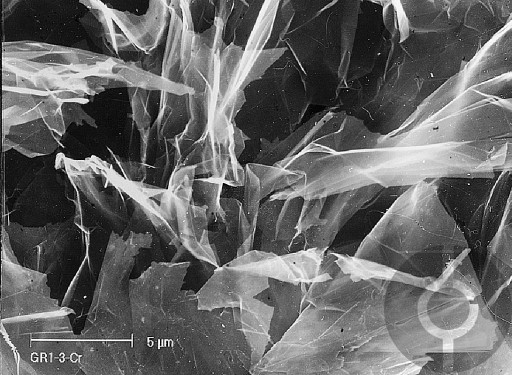

It can be seen as a paradox that graphite, a very soft and pliant substance, is formed of the same element, carbon, which produces the diamond, the hardest material known in nature. The difference between the two materials is all in their crystalline structure: while diamond shows a tetrahedral crystal lattice (sp3 hybridisation) symmetric in the three directions, graphite’s structure is hexagonal (sp2 hybridisation), with carbon atoms tightly bonded within the planes and loosely bonded between the planes. Such an asymmetry is the cause of the peculiar anisotropy found in the mechanical, thermal and electrical properties of the graphite, as well as of its inherent lubricity.

The flaky microstructure of expanded graphite

Density

The standard density of expanded graphite for sealing application is 1 g/cm3, but it can be requested in the range 0.7 – 1.3 g/cm3: higher density corresponds to lower gas permeability and higher mechanical strength, but also to lower conformability.

Purity

The purity of expanded graphite is evaluated in terms of its carbon content, or, conversely, in terms of its content of ashes, which represent the residue after burning the graphite in air. Such ashes contain mainly harmless elements, like silicon and aluminium, but also contaminants, usually residues from the mineral gangue of the natural graphite, such as quartz, silicates or mica: these disturb the orderly laminar structure of the graphite, producing channels and irregular pores that reduce the sealing effectiveness of the gasket. Moreover, as the ash content increases, the mechanical strength is also reduced and there is a greater risk of corrosion.

In expanded graphite there are usually traces of sulphur, chlorine and fluorine: under certain conditions, these elements can contribute to activate corrosion processes in metallic assemblies, and their content should therefore be minimized.

Properties