Compressed fiber (CSF) jointing sheets, asbestos free material, are manufactured from a viscous granular mixture of high-strength short fibres, heat-resistant fillers, elastomeric binders and various chemicals, which is vulcanised into sheet form under the pressure of two counter-rotating steel rollers (calenders).

The result is a line of highly versatile gasket sheet materials, widely used with pipes and pressure vessels thanks to the ability to effectively seal over an extremely broad range of service conditions.

Product lines:

Sheet dimensions:

Available surface finish: 4AS anti-stick coating on both sides is standard in most styles. PTFE, graphite or silicone coating is also available upon request.

The effectiveness of CSF gaskets is due to their resistance against plastic deformation, provided by a network of reinforcing fibres interlocked with fillers and an elastomeric matrix.

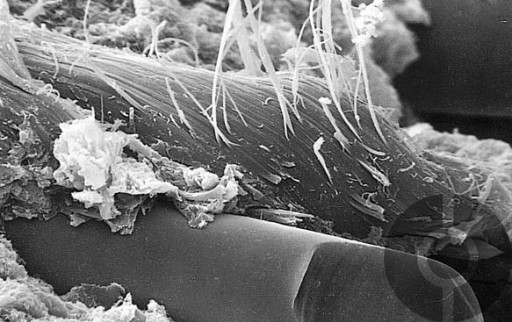

The reinforcing fibres are the most crucial components. They must have high modulus and tensile strength, thermal and chemical stability, and capacity to hook up to the other ingredients. The best performances is shown by aramid fibres, specifically poly-para-phenylene-terephthalamide fibres. These fibres, in a percentage typically ranging from 7 to 15% of the mixture, are present in form of “pulp” of short fibres that undergo a process of fibrillation, which leads to the formation of thin branches (fibrils). Fibrils drastically increase the specific surface of the fibre, so enhancing their interlocking with the other components. Aramid fibres owe their excellent thermal, chemical and mechanical properties to their chemical composition: carbon-nitrogen double bonds provide stiffness to the polymeric chain, which develops along ordered parallel planes. Such a structure, however, is subject to attack by steam, which hydrolyzes the inter-molecular bonds, and by strong acids and alkalis. When such media are present, the integrity of aramid fibres is left up to the shield provided by the rubber matrix.

Glass, mineral, and carbon fibres withstand higher temperature compared to aramid fibres, but they are more brittle, have no fibrils (that is less interlocking ability), and have a tendency to line along the rolling direction during the calendering process, which leads to mechanical anisotropy in the sheets. As a consequence, they are used always in combination with aramid fibres in CSF styles that are suitable for steam and high temperature applications.

For applications with non-aggressive media at low temperature, organic fibres such as polyester and cellulose are used in price-effective products.

The elastomeric binder typically represents 10 to 25% of the sheet weight. Only certain types of rubber can be used, in relation to their rheological properties and ability to wet fibres and fillers. Most common binders are NBR, SBR, NR, CR, EPDM and CSM.

In a CSF gasket it is essentially the binder that blocks the path of the sealed medium by closing the porosity between fibres and fillers, and by matching and filling up all the irregularities of the flange faces. Moreover, it protects the gasket fibres and fillers from chemical attack.

The softening of the binder between 100 and 150°C is beneficial to gasket tightness, as it helps the binder to flow and fill up all porosity. Above this temperature, though, the binder will harden over the time. Nevertheless, since the gasket mechanical properties are provided by the fibres, this effect does not hinder the gasket performance.

In conclusion, the binder is selected essentially with reference to the chemical resistance that it will impart to the gasket. CSM or EPDM binders are used in CSF styles that must operate in chemically-aggressive environments.

The fillers (70 – 80% in weight) have their own relevance too, essentially linked to their shape, specific surface ad electrostatic charge: all factors that affect their ability to intimately mix with the reinforcing fibres. Their structure can be fibrous (rock wool, glass wool, ceramics), flaky (graphite), or granular (kaolin, sulphates, oxide particles, etc.), with dimensions that range from sub-micron to hundreds of microns, and a specific surface that can exceed 100 m2/g, as it is the case for micro-porous active silica.

The composition of CSF can include reinforcing inserts, such as wire net or mesh, or metallic perforated sheet: such inserts increase the capacity of the gasket to withstand compressive load and therefore extend its suitability to higher service pressure.

Micro-photo of aramid Kevlar® (above) and inorganic (below) fibre in FASIT HT sheet. Well-opened fibrils on the Kevlar® fibre surface allow interlocking with the elastomeric matrix, thereby imparting to the material excellent resistance against plastic deformation. This characteristic results in high stress retention and sealing performance of the gasket.